With the quest to combat rising global temperatures and the drive towards renewable energy sources, Solar Panels are increasingly becoming a dominant feature in our everyday lives. More and more people are embracing the use of solar energy and the cost of solar panels are dropping fast with advance in the technology of their manufacture.

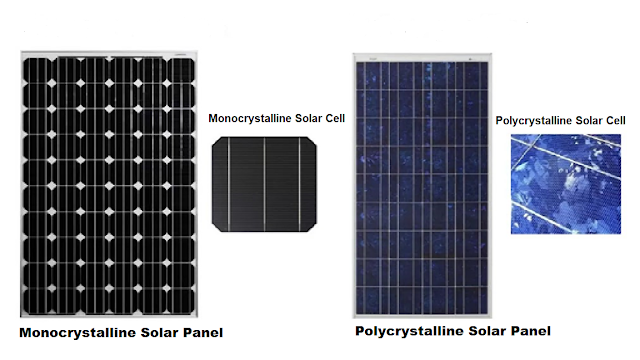

Two common solar Panel types are dominant in today’s solar panels market with varying technologies: Monocrystalline and Polycrystalline panels. Why choose one over the other? We are about to find out.

Monocrystalline Solar Cells

Characteristics of Monocrystalline Cells

|

1 |

Silicon is formed into bars and

cut into waters to form cells |

|

2 |

They are single crystal Silicon |

|

3 |

Electrons have more room to move |

|

4 |

Panel efficiency is 15 – 20% |

|

5 |

Monocrystalline solar cells are more efficient

than Polycrystalline cells |

Polycrystalline Solar Cells

Characteristics of Polycrystalline Cells

|

1 |

They are also made from Silicon |

|

2 |

Produced by melted Silicon fragments

together |

|

3 |

They are also called multicrystalline |

|

4 |

Less freedom for electrons to

move |

|

5 |

Panel efficiency is 13 – 16% |

|

6 |

Polycrystalline solar panels are

less efficient than monocrystalline cells |